When most people picture innovation in the aerospace industry, they envision new airline or aircraft startups that revolutionize the way people travel. But sometimes, the biggest revolutions happen on the ground.

One Delaware-based aviation company is quietly shaping the way airports, FBOs, and MROs move aircraft, and saving them millions of dollars in the process.

A Smarter Way to Move Aircraft

Enter TowFLEXX, an all-electric aircraft tug system designed to eliminate one of aviation's most persistent inefficiencies: parking space. Traditional towbar systems require an exit path for tugs, eating up to 12 feet of additional space with every aircraft parked. TowFLEXX's compact, self-propelled design changes that, allowing operators to pack aircraft more tightly in hangars, sometimes even fitting an extra jet or two in the same building.

Ad by Jetstream Magazine by AeroXplorer.

Ad by Jetstream Magazine by AeroXplorer.

Originally founded in Germany, TowFLEXX established its North American base in Delaware, where it now manages production, distribution, and service for the U.S. market. The company's growth in the states has been rapid, fueled by increasing demand from FBOs, MROs, and corporate flight departments who are looking to reduce hangar costs.

TowFLEXX's website features a vast product line, from small units capable of handling 9,000 pounds up to its strongest unit, TF6, which is rated for 200,000 pounds. Although TF6 is not yet integrated into hangar operations, it is undergoing final testing for pushback operations.

For FBOs and MROs managing fleets of light jets, this efficiency translates directly into revenue and reduced operational costs.

Fully Electric = Fully Efficient

According to TowFLEXX CEO Junaid Mukhtar, the company's product line runs exclusively on electric power. The units are configured with 12-volt LED gel batteries, arranged as either 24-volt (two batteries) or 48-volt (four batteries), depending on the model's operational requirements. Each unit can be charged with a standard 110-volt wall outlet, mitigating the need for any special infrastructure.

Mukhtar also suggests that the tug can save companies more than $16,000 annually in maintenance and fuel costs across periodic oil changes, fuel expenses, and equipment overhauls that plague conventional hydraulic tugs.

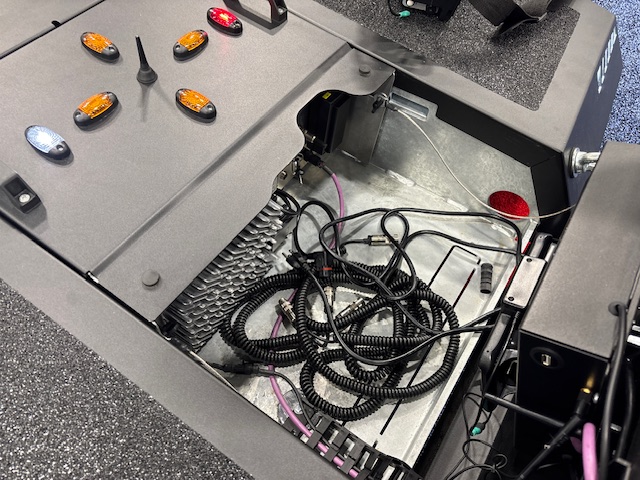

TowFLEXX takes an interesting approach to tug maintenance, focusing on modularity and simplicity. Every component is designed to be, in Mukhtar's words, "plug-and-play," ensuring that if something breaks, it can be replaced without sending the unit offsite. When an issue arises, customers can connect to TowFLEXX's support team through a video call, where the issue can be addressed virtually. Replacement parts are shipped immediately, keeping downtime to a minimum.

"If you can turn a wrench, you can fix the tug," Mukhtar says. "We want to make sure that if you're down, we can get you up and running quickly."

"Everything is made so that things can just be taken apart," Mukhtar added. "If we think something is wrong with [...] a light, you can flip this over, unscrew it, and they're all plugged in on a plug. We'll send you a new light, and you just plug it back into the same connection, and it's ready to go."

Saving Costs

Unlike traditional tow systems, TowFLEXX tugs don't require wing walkers; instead, a controller can stand behind the aircraft with a remote as they guide the aircraft into the hangar. Each unit has a range of approximately 250 feet, more than enough for typical hangar operations. After each sale, TowFLEXX technicians travel to the customer's location to provide on-site training and demonstrate best practices for operation and maintenance, eliminating any learning curves associated with the hangar integration process.

Although the tugs aren't currently certified for aircraft pushback, the TF6 aims to change that, bringing the same electric innovation to larger, heavier aircraft. Because aircraft towing operations are not regulated by the FAA, such movements fall under the category of "at your own risk." This allows companies like TowFLEXX to innovate without bureaucratic delays of certification, giving this sector an edge in innovation as opposed to startups and other OEMs.

Increasing Revenue

In conversation with AeroXplorer, Mukhtar further emphasized the importance of packing aircraft tightly. He shared how, for FBOs and MROs, space is money. Additionally, decreased maintenance overhead and a modular maintenance approach maximize tug operation time – essentially, the tug "pays for itself."

As TowFLEXX expands into higher-weight categories and pushback capabilities, its products may soon become a staple at airports worldwide, quietly moving aircraft (and the industry) towards a smarter, greener, and cheaper future.

Spirit Airlines Projects Net Profitability by 2027 » Bombardier Reveals BOND Behind $1.7B Aircraft Order » Air France Announces Paris-Las Vegas Nonstop Service »

Comments (0)

Add Your Comment

SHARE

TAGS

STORIES TowFLEXX Startups Startup Tug Pushtug FBO MRO Logtistics Ground HandlingRECENTLY PUBLISHED

Air France Announces Paris-Las Vegas Nonstop Service

Air France is expanding its US operations with a new nonstop service from Paris to Las Vegas, significantly enhancing travel options between these two cities. This strategic move not only benefits travelers but also promises economic growth and cultural exchange, while positioning Air France as a key player in the competitive transatlantic market.

ROUTES

READ MORE »

Air France Announces Paris-Las Vegas Nonstop Service

Air France is expanding its US operations with a new nonstop service from Paris to Las Vegas, significantly enhancing travel options between these two cities. This strategic move not only benefits travelers but also promises economic growth and cultural exchange, while positioning Air France as a key player in the competitive transatlantic market.

ROUTES

READ MORE »

PHOTOS: Inside Gulfstream's New G800, the World's Longest-Range Business Jet

Inside Gulfstream's new G800, showcased at NBAA-BACE 2025.

STORIES

READ MORE »

PHOTOS: Inside Gulfstream's New G800, the World's Longest-Range Business Jet

Inside Gulfstream's new G800, showcased at NBAA-BACE 2025.

STORIES

READ MORE »

Inside IndiGo's Game-Changing Order for 30 Airbus A350 Aircraft

IndiGo has announced a significant order for 30 Airbus A350 aircraft, marking a strategic move to expand its operations into the long-haul market. This investment not only supports its growth ambitions but also aligns with broader efforts towards sustainability in aviation.

NEWS

READ MORE »

Inside IndiGo's Game-Changing Order for 30 Airbus A350 Aircraft

IndiGo has announced a significant order for 30 Airbus A350 aircraft, marking a strategic move to expand its operations into the long-haul market. This investment not only supports its growth ambitions but also aligns with broader efforts towards sustainability in aviation.

NEWS

READ MORE »